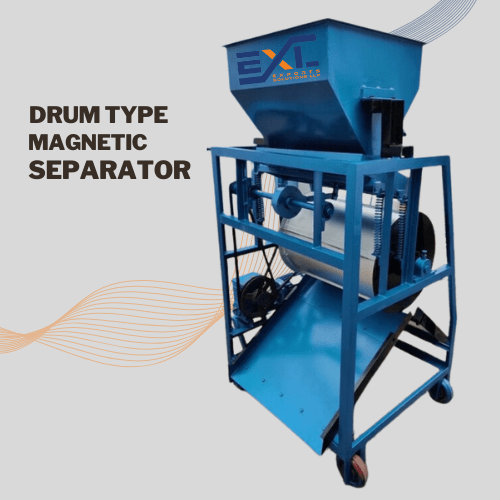

Drum Type Magnetic Separator offers a practical solution by efficiently removing ferrous materials from dry or granular products, ensuring both product purity and equipment protection.

At EXL Exports, one of India’s top exporters and suppliers of magnetic separation equipment, we provide Drum Type Magnetic Separators that are designed for high performance, durability, and easy integration into your production line. In this post, we’ll explore the features, benefits, and applications of this powerful magnetic separator and how it can enhance your industrial operations.

Why You Need a Drum Type Magnetic Separator in Industrial Processes

Ferrous contamination can significantly impact the efficiency and safety of your industrial operations. In industries such as mining, recycling, and manufacturing, small metal contaminants can not only reduce the quality of your products but also cause wear and tear on your equipment. The Drum Type Magnetic Separator is designed to capture and remove ferrous particles from bulk material streams, ensuring cleaner output and protecting your machinery from potential damage.

Key Benefits of the Drum Type Magnetic Separator:

- Effective Metal Separation:

The separator’s high-intensity magnetic field captures and removes ferrous contaminants from materials like minerals, plastics, or other bulk materials, resulting in a cleaner, higher-quality product. - Protection for Machinery:

Ferrous contaminants can cause damage to sensitive machinery downstream, leading to expensive repairs and unplanned downtime. By removing metal particles early in the process, the drum separator helps extend the lifespan of your equipment and maintain operational efficiency. - Continuous, Uninterrupted Operation:

With its rotating drum design, the separator provides continuous separation of ferrous contaminants without the need for frequent stops or adjustments. This makes it ideal for high-volume, uninterrupted production lines. - Durable and Built to Last:

Constructed from high-grade stainless steel, the drum separator is designed to withstand harsh industrial environments and provide long-lasting performance, even in demanding applications like mining and recycling. - Low Maintenance for Maximum Uptime:

The simple and easy-to-clean design ensures minimal downtime for maintenance. Regular cleaning can be completed quickly, allowing the separator to keep your production line running efficiently.

Key Features of the Drum Type Magnetic Separator

The Drum Type Magnetic Separator from EXL Exports incorporates advanced magnetic technology and durable construction to ensure optimal performance in industrial environments. Here’s what makes it stand out:

- High-Intensity Magnetic Force:

Equipped with powerful neodymium magnets, the separator generates a strong magnetic field that effectively attracts and holds ferrous contaminants. This ensures the separation of metal particles from non-magnetic materials, leading to cleaner output. - Robust Stainless Steel Construction:

Built to handle the toughest industrial environments, our separators are constructed from industrial-grade stainless steel that is resistant to wear, corrosion, and impact. This ensures long-lasting reliability, even in continuous-use scenarios. - Continuous Operation for High-Volume Processing:

The rotating drum allows for the constant removal of ferrous contaminants, making it ideal for high-volume industrial applications that require uninterrupted operation. It’s a great fit for large-scale processing plants in mining, recycling, and heavy manufacturing. - Low Maintenance Design:

The separator is designed for easy cleaning and minimal maintenance, reducing downtime and helping you keep your production line moving. The collected metal particles can be quickly removed and the drum put back into service with minimal interruption. - Customizable Sizes and Configurations:

We offer drum separators in a range of sizes and configurations to suit your specific operational needs. Whether you require a standard size or a custom solution, we can provide the right product to integrate into your existing system.

How Does the Drum Type Magnetic Separator Work?

The Drum Type Magnetic Separator operates using a simple but highly effective design. Here’s how it works:

- Material Feed:

Bulk materials—whether dry powders, granular products, or minerals—are fed onto a conveyor or directly onto the magnetic drum surface. - Magnetic Separation:

As the material passes over the rotating drum, the high-intensity magnetic field attracts and captures ferrous contaminants, such as iron shavings, metal particles, or tramp iron. These contaminants adhere to the surface of the drum while the clean material continues through the process. - Discharge of Contaminants:

Once the drum rotates past the magnetic field, the captured ferrous particles are discharged into a separate collection bin, ensuring that the final product remains free from metal contamination. - Easy Cleaning and Maintenance:

The drum separator is designed for quick and easy cleaning. When enough contaminants have accumulated, they can be removed from the drum’s surface with minimal disruption to the production process, allowing continuous operation.

This simple yet effective process ensures that your materials are free from harmful ferrous contaminants, improving product quality and protecting your equipment from damage.

Applications of the Drum Type Magnetic Separator

The Drum Type Magnetic Separator is widely used in industries that handle bulk materials and require efficient metal separation. Here are some of the key industries and applications where drum separators are indispensable:

Mining Industry:

- Metal-Free Ore Processing:

In mining operations, the presence of ferrous contaminants can affect the quality of processed ores such as iron ore, gold, and other minerals. Drum separators help remove these contaminants, ensuring clean output and preventing damage to milling and crushing equipment.

Recycling Industry:

- Metal Recovery and Sorting:

In recycling plants, ferrous metals must be separated from non-ferrous materials like plastic, glass, and paper. Drum magnetic separators capture ferrous metals from mixed material streams, ensuring clean, contaminant-free output that improves the efficiency of recycling operations.

Plastics and Chemical Manufacturing:

- Contaminant-Free Production:

In plastics and chemical industries, the presence of ferrous particles can compromise product quality and damage sensitive machinery. Drum separators efficiently remove these contaminants from resins, powders, and granules, ensuring the purity of materials used in production.

Why Choose EXL Exports for Your Drum Type Magnetic Separator?

As one of India’s top exporters and suppliers of magnetic separation solutions, EXL Exports is committed to providing high-performance Drum Type Magnetic Separators that meet the needs of various industrial applications. Our products are designed for efficiency, durability, and ease of use, making them an essential tool for industries focused on quality control and equipment protection.

Here’s why customers trust us:

- Advanced Magnetic Technology:

Our drum separators are equipped with high-powered neodymium magnets that ensure effective separation of ferrous contaminants, providing cleaner products and protecting your equipment. - Industrial-Grade Durability:

Made from high-quality stainless steel, our separators are built to withstand the most demanding industrial environments, ensuring long-lasting performance. - Competitive Pricing and Fast Shipping:

We offer competitive prices without compromising on quality. Plus, our fast shipping and hassle-free returns ensure that you get the products you need, when you need them. - Custom Solutions Available:

We provide a variety of sizes and configurations to meet the specific needs of your industry. Whether you require a standard product or a custom solution, we can deliver the right drum separator for your operation.

Ready to Optimize Your Material Handling with a Drum Type Magnetic Separator?

If you’re looking for a cost-effective, high-performance solution to remove ferrous contaminants from your bulk materials and protect your equipment, the Drum Type Magnetic Separator is the perfect choice. With its continuous operation, robust construction, and powerful magnetic force, it’s an essential tool for industries such as mining, recycling, and manufacturing.

Order Now!

Contact us today to order your Drum Type Magnetic Separator and experience fast shipping, competitive pricing, and professional support from India’s leading exporter and supplier of magnetic separation solutions.

FAQs About Drum Type Magnetic Separators:

What industries commonly use Drum Type Magnetic Separators?

Common industries include mining, recycling, plastic processing, and chemical manufacturing, where ferrous contamination needs to be controlled.

What types of materials can the Drum Type Magnetic Separator process?

It’s designed to handle bulk materials such as dry powders, minerals, plastic granules, and more, efficiently removing ferrous contaminants.

How does the Drum Type Magnetic Separator work?

It uses a rotating magnetic drum to attract and capture ferrous contaminants while allowing clean, non-magnetic materials to pass through.

Is the separator suitable for large-scale operations?

Absolutely! The drum separator is ideal for high-volume, continuous operations in industries such as mining, recycling, and manufacturing.