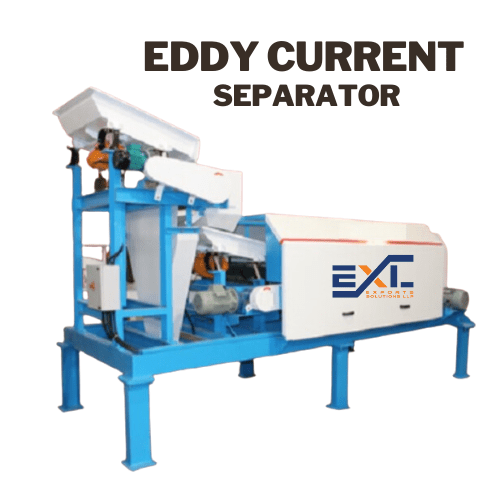

In industries where the separation of non-ferrous metals like aluminum, copper, and brass is critical, the Eddy Current Separator offers an innovative solution. Whether you’re running a recycling plant, waste management facility, or a metal processing operation, effective metal separation ensures better product quality, reduced contamination risks, and smoother operational flow.

Offered by EXL Exports, a leading exporter and supplier in India, our Eddy Current Separator is engineered with advanced technology and built for durability, making it a must-have for large-scale industrial applications.

In this post, we’ll dive into how the Eddy Current Separator works, its key features, and the benefits it brings to industries like recycling, mining, and manufacturing.

Why You Need an Eddy Current Separator for Your Industrial Process

Whether you’re managing a recycling facility or involved in the extraction of valuable metals from mixed materials, a Eddy Current Separator is essential. Non-ferrous metals—such as aluminum, copper, and brass—can often get mixed with other materials like plastics, glass, or shredded scrap, reducing the purity and value of the final product. The Eddy Current Separator provides a highly efficient way to remove these metals, ensuring superior output quality.

Key Benefits of the Eddy Current Separator:

- Superior Metal Separation:

Utilizing advanced eddy current technology, the separator efficiently distinguishes between non-ferrous metals and non-metallic materials. This results in cleaner end products with significantly reduced contamination. - High Processing Capacity:

The separator is designed to handle large-scale, high-speed operations, making it perfect for industries with heavy processing loads such as recycling plants, scrap metal facilities, and mining operations. - Energy-Efficient Operation:

With an energy-optimized design, the separator consumes less power while still delivering excellent separation results. This not only reduces operational costs but also supports eco-friendly manufacturing practices. - Durable and Low Maintenance:

The industrial-grade construction ensures that the separator can withstand the rigors of continuous use, even in challenging environments. Plus, its low-maintenance design minimizes downtime, allowing for smooth, uninterrupted operations. - Versatile Across Industries:

From recycling to metal recovery, the Eddy Current Separator is versatile enough to be used in a range of industries. It effectively separates non-ferrous metals from plastics, electronic waste, and even shredded scrap, making it a valuable addition to any processing line.

Key Features of Our Eddy Current Separator

The Eddy Current Separator from EXL Exports is equipped with cutting-edge technology and is specifically designed to meet the demands of industrial applications. Here’s a closer look at the features that make it stand out:

- Innovative Eddy Current Technology:

The heart of the machine is its high-power magnetic rotor, which generates eddy currents to repel non-ferrous metals. This technology allows for precise separation of materials such as aluminum, copper, and brass from mixed waste streams, ensuring high-purity output. - Durable Construction:

Built from high-quality, industrial-grade materials, the separator is designed to operate in heavy-duty environments. It can handle the challenges of continuous use, ensuring a long service life and consistent performance. - High Volume Capacity:

The separator is optimized for high-speed, high-volume processing, making it suitable for large operations like recycling facilities, mining operations, and scrap metal processing plants. - Energy-Efficient Design:

The system is engineered to offer excellent separation efficiency while consuming less energy. This not only helps reduce operational costs but also supports businesses aiming for sustainable and eco-friendly processes. - Low Maintenance Requirements:

The separator is designed with fewer moving parts, reducing the need for frequent servicing. This allows for minimal downtime, keeping your operations running smoothly and improving overall productivity. - Versatile Application:

Whether you’re separating metals from shredded scrap, electronic waste, or plastics, the Eddy Current Separator is capable of handling a diverse range of materials, making it adaptable to a variety of industrial needs.

How Does the Eddy Current Separator Work?

The Eddy Current Separator operates using a combination of magnetic fields and eddy currents to efficiently separate non-ferrous metals from other materials. Here’s a quick look at how it works:

- Material Feed:

Mixed materials—containing both non-ferrous metals and non-metallic materials—are fed onto a conveyor belt. - Magnetic Separation:

As the material moves across the conveyor, it passes over a fast-rotating magnetic drum that generates eddy currents. These currents cause non-ferrous metals (such as aluminum or copper) to be repelled and separated from non-metallic materials, which continue along the conveyor. - Material Sorting:

The separated non-ferrous metals are then diverted into a separate collection area, while the remaining non-metallic materials are discharged through another exit point. This process ensures that only clean, pure metals are recovered.

By the end of this separation process, you’ll have two distinct material streams: one containing non-ferrous metals and the other composed of non-metallic materials, ready for further processing or disposal.

Applications of the Eddy Current Separator

This versatile machine finds applications in various industries where efficient metal separation is critical. Let’s explore its main uses:

Recycling Industry:

- Metal Recovery:

The Eddy Current Separator is widely used in recycling plants to separate valuable non-ferrous metals like aluminum, copper, and brass from plastic, glass, and other materials. This ensures cleaner, higher-quality metal for resale or further processing.

Waste Processing:

- Efficient Metal Extraction:

In waste management, separating metals from waste streams is essential for both economic recovery and environmental protection. The separator helps extract non-ferrous metals from municipal solid waste, making the recycling process more profitable and eco-friendly.

Mining and Quarrying:

- Enhanced Mineral Purity:

In mining operations, the separator ensures the effective recovery of valuable metals from mixed ores, improving the purity of extracted minerals and supporting more efficient downstream processes.

Scrap Metal Processing:

- Valuable Metal Recovery:

Scrap yards use the Eddy Current Separator to recover valuable non-ferrous metals from mixed scrap, ensuring that the recovered material is free from contamination and has a higher resale value.

Why Choose EXL Exports for Your Eddy Current Separator?

As a leading exporter and supplier in India, EXL Exports delivers high-performance Eddy Current Separators designed for reliability, efficiency, and versatility. We are dedicated to providing machines that not only improve product quality but also optimize operational efficiency across a variety of industries.

Here’s why customers trust us:

- Innovative Technology:

We incorporate advanced eddy current technology to ensure precise and efficient separation of non-ferrous metals. - Industrial-Grade Durability:

Our machines are built to withstand harsh conditions, ensuring long-lasting performance even in the toughest environments. - Energy Efficiency:

Our separators are designed to deliver excellent results with minimal energy consumption, reducing operational costs and promoting sustainability. - Fast Shipping & Easy Returns:

We offer prompt delivery and easy return policies, ensuring a hassle-free experience from purchase to setup.

Ready to Optimize Your Metal Separation Process?

If you’re looking for a high-performance solution to enhance your metal separation, reduce contamination, and improve product quality, the Eddy Current Separator is your go-to machine. Whether you operate in recycling, mining, waste management, or scrap metal processing, this separator delivers unmatched efficiency and reliability.

Order Now!

Take the next step toward optimizing your operations with our Eddy Current Separator. Contact us today for more information, and experience quick shipping and hassle-free returns from India’s leading exporter and supplier of metal separation solutions.

FAQs About Eddy Current Separators:

Can it handle various types of materials?

Absolutely! It’s effective for a wide range of materials, including shredded scrap, electronic waste, plastics mixed with metals, and more.

Yes! We offer customizable roller diameters and widths, as well as multi-stage configurations to suit specific industrial needs.

What types of metals can the Eddy Current Separator handle?

It’s designed to separate non-ferrous metals such as aluminum, copper, and brass from mixed materials.

How does the Eddy Current Separator work?

It uses high-speed magnetic fields to generate eddy currents that repel non-ferrous metals, separating them from non-metallic materials.

Is the separator suitable for high-volume operations?

Yes! The Eddy Current Separator is designed for large-scale, high-speed processing, making it ideal for industries like recycling and waste management.