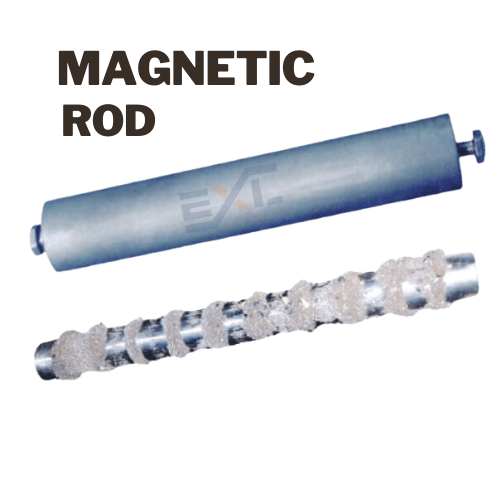

At EXL Exports, one of India’s leading exporters and suppliers of magnetic solutions, we offer Magnetic Rods (also known as Magnetic Tubes or Magnetic Bars) that provide a powerful, durable, and easy-to-install solution for removing ferrous contaminants. In this post, we’ll explore the features, benefits, and applications of our magnetic rods, and how they can improve your production line.

Why You Need Magnetic Rods for Metal Contaminant Removal

Ferrous metal contaminants can enter materials at various stages of the production process, affecting the quality of your final product and potentially damaging machinery. These contaminants can be as small as iron dust or larger pieces like metal shavings. A Magnetic Rod is a simple yet highly effective solution that captures these particles, ensuring cleaner materials and smoother operations.

Key Benefits of Magnetic Rods:

- Superior Metal Contaminant Removal:

Our magnetic rods use high-powered magnets to capture even the smallest ferrous particles, ensuring your product is contaminant-free. This not only protects your downstream equipment but also guarantees product quality. - Versatile Design for Easy Integration:

Whether you need to install the magnetic rod in hoppers, bins, chutes, or pipelines, our versatile design allows for easy integration into a wide range of processing systems. You can adapt them to fit the specific needs of your production line without any major modifications. - Cost-Effective and Durable:

Built from high-grade stainless steel, our magnetic rods are resistant to wear and corrosion, providing long-lasting performance in industrial environments. This durability ensures that your investment will pay off with consistent results over time. - Easy Installation and Minimal Maintenance:

Magnetic rods can be easily installed without disrupting the flow of materials. With low maintenance requirements and easy cleaning, they allow you to focus on production rather than equipment upkeep. - Increased Operational Efficiency:

By removing metal contaminants before they can damage equipment or lower product quality, magnetic rods help reduce downtime, extend the lifespan of your machinery, and improve overall operational efficiency.

Key Features of Magnetic Rods

The Magnetic Rods from EXL Exports are designed with advanced technology to ensure effective metal separation while maintaining durability and ease of use. Here’s what makes them a great addition to your production process:

- High Magnetic Strength:

Our rods are equipped with strong neodymium magnets that provide superior attraction power. This ensures that even the smallest ferrous contaminants, such as fine iron particles or metal shavings, are efficiently captured and removed from the material flow. - Robust Construction for Industrial Use:

Made from high-quality stainless steel, the rods are resistant to both wear and corrosion, ensuring that they stand up to harsh industrial environments. Whether in food processing or mining operations, these rods are built to last. - Variety of Sizes and Configurations:

We offer magnetic rods in various lengths and diameters to fit different processing setups. This versatility means they can be tailored to your exact specifications, ensuring seamless integration into your existing systems. - Simple Installation and Maintenance:

Designed for easy installation, our magnetic rods can be placed inside hoppers, bins, chutes, or pipelines without interrupting the material flow. They are also easy to clean, ensuring minimal downtime during maintenance.

How Do Magnetic Rods Work?

The operation of Magnetic Rods is straightforward but incredibly effective. Here’s how they work:

- Material Flow:

Free-flowing materials—whether in powder, granule, or liquid form—pass through the system where the magnetic rod is installed, typically inside a hopper, chute, or bin. - Magnetic Attraction:

As the materials flow past the magnetic rod, the magnetic field generated by the rod attracts and captures any ferrous particles, such as iron filings, metal shavings, or other magnetic contaminants. - Clean Material Discharge:

The cleaned materials, free from ferrous contaminants, continue through the processing line, ensuring the purity of the product and protecting downstream machinery from potential damage. - Easy Contaminant Removal:

When the rod is full of collected metal particles, it can be easily removed for cleaning. This ensures continuous operation with minimal downtime for maintenance.

This simple yet effective process ensures that your materials are free from ferrous contaminants, safeguarding both your product quality and your equipment.

Applications of Magnetic Rods

Magnetic rods are used across a wide range of industries where metal contamination control is critical. Let’s explore some of the key sectors that benefit from the use of Magnetic Rods:

Food Processing Industry:

- Product Purity:

In the food industry, removing metal contaminants is essential for maintaining product safety and quality. Magnetic rods help capture metal particles in grain, sugar, flour, and other food products, ensuring compliance with industry standards and regulations.

Chemical Industry:

- Contaminant-Free Production:

In chemical processing, even trace amounts of metal contaminants can compromise the quality of the final product. Magnetic rods ensure that your chemicals remain pure, helping maintain product consistency and integrity.

Pharmaceutical Industry:

- Metal-Free Medicine:

In pharmaceuticals, preventing contamination is critical to ensuring the safety and efficacy of the medication. Magnetic rods are used to remove any metal contaminants from powders and granules during the production of drugs and supplements.

Plastics and Recycling Industries:

- Metal Separation and Recovery:

In plastic manufacturing and recycling plants, magnetic rods are used to separate metal particles from resins or recycled materials, ensuring a clean product stream and helping recover valuable metals from waste streams.

Mining and Minerals:

- Material Purity in Mining Operations:

Magnetic rods are essential in mining and mineral processing to capture tramp metal and ensure the purity of minerals like iron ore, quartz, or silica, while protecting the processing equipment from damage.

Why Choose EXL Exports for Your Magnetic Rods?

As one of the leading exporters and suppliers in India, EXL Exports is committed to providing high-quality Magnetic Rods that meet the diverse needs of various industries. Our products are designed for performance, durability, and ease of use, making them a valuable addition to any industrial process.

Here’s why customers trust us:

- Advanced Magnetic Technology:

Our magnetic rods use powerful neodymium magnets to ensure maximum contaminant removal, even in demanding environments. - Industrial-Grade Durability:

Constructed from high-quality stainless steel, our magnetic rods are built to withstand wear and corrosion, ensuring long-lasting performance in harsh conditions. - Versatile and Customizable:

We offer a range of sizes and configurations to suit your specific production requirements, making it easy to integrate our magnetic rods into your existing systems. - Competitive Pricing and Fast Shipping:

We offer competitive prices and quick shipping, ensuring that you get the best value without compromising on quality. Plus, we offer easy returns for a hassle-free purchasing experience.

Ready to Enhance Your Industrial Processes with Our Magnetic Rods?

If you’re looking for a cost-effective and efficient solution to remove ferrous contaminants, protect your equipment, and ensure product purity, our Magnetic Rods are the ideal choice. With their strong magnetic power, durable construction, and easy-to-install design, these rods are a must-have for any industrial production line.

Order Now!

Contact us today to order your Magnetic Rods and experience fast shipping, competitive pricing, and professional support from India’s leading exporter and supplier of magnetic solutions.

FAQs About Magnetic Rods:

What industries use Magnetic Rods?

Magnetic rods are commonly used in food processing, pharmaceuticals, plastics, recycling, chemical processing, and mining industries where metal contamination needs to be controlled.

What materials can the Magnetic Rod handle?

Magnetic rods are designed to capture ferrous contaminants from free-flowing powders, granules, and liquids, making them suitable for use in a wide range of industries.

How do I clean the Magnetic Rods?

The magnetic rods are easy to clean—simply remove them from their housing, wipe off the collected contaminants, and reinstall them for continuous use.

Can Magnetic Rods be used in food processing?

Yes! Magnetic rods are widely used in food processing to ensure product purity by removing metal particles from ingredients like flour, sugar, and grains.