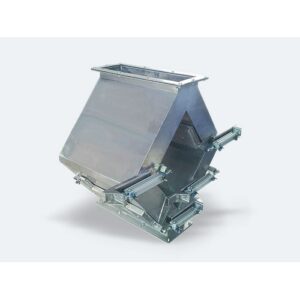

Wet Drum Permanent Magnetic Separator

Wet Drum Permanent Magnetic Separator – Exporter and Supplier in India

Efficient Wet Drum Permanent Magnetic Separator for Industrial Applications

Our Wet Drum Permanent Magnetic Separator is designed to remove very fine magnetisable components from low-concentration, low-viscosity liquids. Supplied by the best exporter and supplier in India, this separator is ideal for use in the metal processing industry and for treating pre-concentrates extracted from high-gradient magnetic filters. With the ability to separate up to 90% of grain sizes ranging from 1 µm to 1000 µm as sludge, this product ensures optimal performance.

General Principle

The wet drum separator operates by directing the liquid through a semicircular separating chamber located beneath a stainless steel drum. Magnetisable particles are attracted to the high-gradient magnetic field generated by permanent magnetic discs positioned inside the drum. These strong magnetic fields make the separator particularly effective for removing even the finest contaminants, ensuring the purity of the product stream.

Key Features:

- High Magnetic Recovery: Offers excellent magnetic recovery, ensuring optimal separation of fine ferrous particles.

- Durable Stainless Steel Drum: The drum is made from thick stainless steel, designed to withstand harsh industrial conditions for long-lasting performance.

- Automatic Magnetic Recovery: Recovers magnetic components from the feed slurry, ensuring efficient processing.

- Multiple Configurations Available: Available in single, double, and multiple drum configurations to meet diverse industrial needs.

- Permanent Magnet Assembly: Eliminates the need for coil burn-outs, increasing the product’s reliability and reducing maintenance costs.

- Corrosion-Resistant Construction: This is protected by a special coating that prevents rust and wear, enhancing the longevity of the separator.

How It Works:

The liquid flows through a semicircular chamber beneath the stainless steel drum. Permanent magnetic discs attract magnetizable particles, which are then lifted out of the slurry as the drum rotates. This process separates the ferrous contaminants, allowing the purified product to flow out of the system. The separator is equipped with powerful rare-earth magnets that enable the removal of even the weakest contaminants from dense materials.

Salient Features:

- Efficient Magnetic Recovery: High magnetic recovery rate and excellent discharge.

- Multiple Drum Configurations: Single drum, double drum, or multi-drum options.

- Robust Construction: Designed with a thick stainless steel drum and permanent magnet assembly.

- Versatile Applications: Used in various industries such as mining, plastics, food processing, and more.

Applications:

Our Wet Drum Permanent Magnetic Separators are widely used in:

- Glass Industry

- Chemical Industry

- Plastic Industry

- Mining Industry

- Food Industry

- Pharmaceutical Industry

- Foundry Industry

They are particularly effective in recovering magnetic and ferrosilicon materials in dense media plants and iron ore processing.

Why Choose Our Wet Drum Separator?

As the best exporter and supplier in India, we deliver Wet Drum Permanent Magnetic Separators that meet the highest standards of quality, durability, and performance. These separators improve plant productivity by removing contaminants from the product stream, ensuring optimal purity. Whether you need to remove fine magnetic particles or heavy magnetic loads, our separator ensures reliable and efficient performance in any industrial setting.

Order Now

Enhance the efficiency of your separation processes with our reliable Wet Drum Permanent Magnetic Separator from the best exporter and supplier in India. Enjoy fast shipping and easy returns.

Explore More: Premium Magnetic Separators and Equipment.