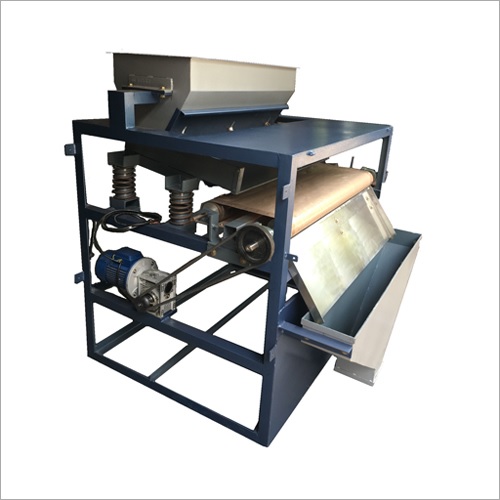

Roller Type Magnetic Separator

We deal in cost-effective, high-intensity, high-gradient, permanent magnetic roller separators with indigenous technology that has been used successfully in industrial minerals applications.

High-intensity roller-type magnetic separator incorporates high-energy rare-earth neodymium permanent magnetic roll assembly and is manufactured and assembled under strict quality control and specification to generate unsurpassed magnetic field gradients. Under this high-intensity magnetic field, weak magnetic contamination can be easily removed easily and efficiently.

Salient Features:

- Magnetic Rollers are available in 75mm(3 inches), 100mm(4 inches), 150mm(6 inches) , 200mm (8 inches), 240mm(9.5inches) diameter & widths up to 2000mm

- A 0.5 HP, variable speed DC/AC geared motor drive adjustable from 0 to 280 RPM drives the roll

- Vibratory feeder provided with high-quality unbalanced vibratory motors

- Abrasion-resistant endless conveyor Belts with a thickness of 0.35mm are provided for the Machine

- Vibratory Feeder with controls provided for Feeding

- The high efficiency of the iron separation system

- Multi-stage system up to 6 stages is available

- Different Magnetic Strengths are available:

- 8,000 Gauss

- 10,000 to 11,000 Gauss

High-Intensity Roller Type Magnetic Separator is used for Cleaning and Processing various types of Grains:

- Rice Cleaning

- Wheat Cleaning

- Corn Cleaning

- Pulses Cleaning Spices

- Cleaning Seed Cleaning

- Semolina Cleaning

- Chilli Flakes

- Sesame Cleaning

- Cumin Cleaning

- Fennel Seed Cleaning

Applications:

Our Magnetic Destoner machines are mostly used in various industries like mineral applications such as abrasive, refractory, and ceramic raw material beneficiation, alumina, silica, carbide, magnesite, quartzite, glass raw materials, quartz, feldspar, dolomite, etc.

Ultra-high purity quartz cleaning, graphite upgrading, manganese ore beneficiation, bauxite upgrading, diamond ore beneficiation, selective separation of garnet/ilmenite/rutile, zircon, beneficiation of iron ore, recovery of metals from slag, removal of ferrous silicates from limestone, magnesite, etc.

Our roller-type magnetic separators are also used for food processing industries.